How To Repair Old Woodworking Machines

Synopsis: If yous're thinking of restoring an one-time machine, it's important to realize that many old machines are but a lot of cast fe with potential. The important question to enquire earlier diving in, says Robert M. Vaughan, is whether the restored car volition exist worth your trouble. Vaughan discusses the general procedures mutual to restoring any old woodworking auto. He starts by talking about how to move the machine (bring enough of baggies for nuts and bolts), and covers inspection, cleaning, rust removal, machinery repairs, painting, electrical repairs, and how much information technology cost him overall to repair a bandsaw. Side information discusses edifice a machinery stand and the specific procedures Vaughan used to restore a Walker-Turner bandsaw.

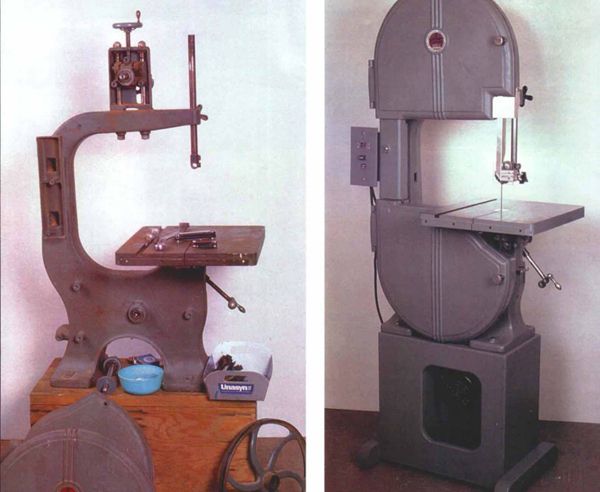

What a deal—a sixteen-in. WalkerTurner bandsaw for $eighty. All information technology needed was new tires, guides, motor, electricals, guards, stand, consummate disassembly, cleaning and rust removal, one casting weld, repainting, reassembly and, of course, realignment of all the parts during reassembly. The adept news was that all of the crucial components were there and in good condition; the other stuff I could gear up. This wasn't an $80 bandsaw, but an $80 bandsaw kit. It was upwardly to me to turn it back into a bandsaw.

I had to weigh the value of the restored bandsaw against commercially available machines. A resaw capacity of 12 in., 400 lbs. of quality American cast atomic number 26 and a 16-in. throat depth are all factors that made this moderate-sized machine worth restoring. If this had been 1 of WalkerTurner's 14-in. models, I would have passed. The work required to restore information technology would have been the same, only the result would have been little better than a new Powermatic or Delta xiv-in. model.

If yous're thinking of restoring an former machine, it's of import to realize that it's a very rare old machine that's ready to run. Almost all are like this automobile was—a lot of cast fe with potential. Bearings, belts, pulleys, switches, wires and motor almost always demand replacement. I reason that bandsaws are so popular to restore is that the parts that habiliment out can almost always exist obtained from sources other than the original manufacturer. The of import question to ask earlier diving into a restoration is whether the restored machine will be worth your problem.

In this article, I'll discuss the general procedures common to restoring any old woodworking machine, too as the more specific procedures that were necessary to get this bandsaw back into elevation grade. And while the general procedures are applicable to just about any machine restoration, even the bandsaw-specific procedures illustrate ways of addressing problems common to all woodworking equipment—ways, for example, of dealing with dust, alignment problems and beatup or missing guards. The principles of machinery restoration are the aforementioned regardless of the machine.

Moving the machine

Moving any heavy machine from one shop to some other is always a chore. At that place are no rules on how to reach it other than to be prepared. I accept assist on paw for lifting. I by and large bring resealable plastic bags for nuts and bolts and a note pad to record the disassembly sequence and to label parts bags. I likewise bring wrenches and WD-40 for disassembly of whatever heavy or protruding parts that might impede handling. I frequently remove the table, and any guards or pulleys, and I ever endeavour to remove the motor and cord. I brand sure in that location are a couple of floor floats (iv casters on a piece of plywood) set up in my shop, then I tin can move the motorcar effectually during the restoration process.

From Fine Woodworking #98

For the full article, download the PDF beneath:

Download FREE PDF

View PDF

Source: https://www.finewoodworking.com/1993/02/01/restoring-vintage-machinery

Posted by: hawkinsausiout.blogspot.com

0 Response to "How To Repair Old Woodworking Machines"

Post a Comment